Step-by-Step Guide to the Electrolytic Copper Foil Test Line Process and Technology

5 min readElectrolytic copper foil is at the heart of many advanced industrial applications — from printed circuit boards (PCBs) to lithium-ion batteries, where its electrical conductivity, mechanical strength, and surface characteristics are mission-critical. To ensure that copper foil meets rigorous quality and performance standards, manufacturers and researchers use a specialized system known as an electrolytic copper foil test line. This comprehensive test line enables continuous electrolysis, precise quality monitoring, and process optimization prior to full-scale production.

In this detailed step-by-step guide, we’ll walk through the core processes and technologies used in an electrolytic copper foil test line. We’ll also highlight how leading equipment provider Timonic (Suzhou) Technology Co., Ltd. supports innovation in this field with advanced machinery and technical expertise, providing vital support to industries such as electronics and energy storage.

About Timonic (Suzhou) Technology Co., Ltd.

Timonic (Suzhou) Technology Co., Ltd. is a specialized industrial equipment manufacturer focused on advanced copper foil production systems, particularly for the *lithium-ion battery and PCB sectors. As a subsidiary of China Special Metal Group Limited (CSM), Timonic is headquartered in Suzhou, Jiangsu Province, and leverages decades of experience in metallurgy and production equipment design. Its product range includes copper foil test lines, copper foil machines, cathode rolls, and customized automation systems — all engineered for precision manufacturing and high reliability.

Timonic’s mission centers on providing turnkey solutions, enabling customers to establish complete copper foil production lines with intelligent mechanical-electrical integration and strong process control.

What Is an Electrolytic Copper Foil Test Line?

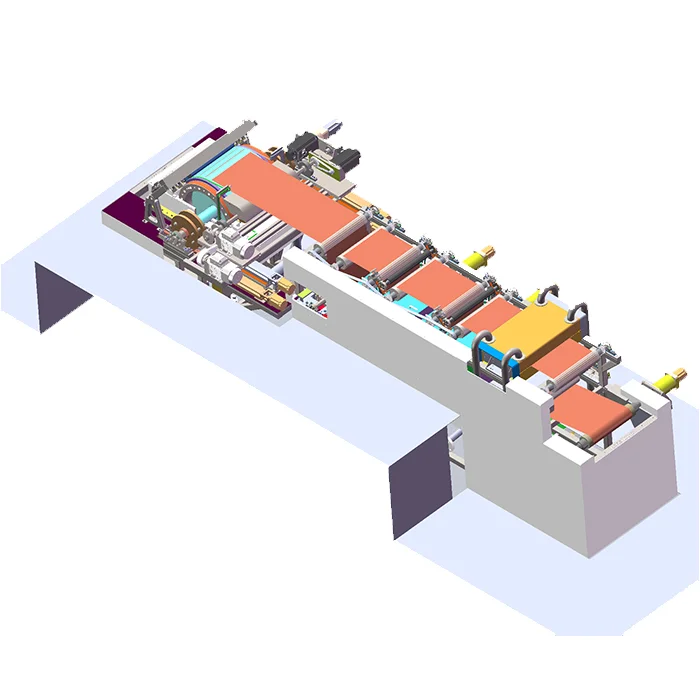

An electrolytic copper foil test line is a specialized assembly line used to research, trial, and optimize the electrolysis-based continuous production of copper foil. It reproduces the full manufacturing environment required to produce copper foil films of defined thickness, width, and consistency, allowing engineers to validate material performance and calibrate process parameters before committing to large-scale operations.

The test line includes:

-

Electrolyte preparation and supply system

-

Filtration and dosing systems

-

Heating and temperature control modules

-

Electrolysis cell with cathode drum

-

Measurement and monitoring equipment

-

Distributed control and automation infrastructure ﹘ all integrated to enable consistent, repeatable test runs.

Why This Test Line Matters

Copper foil quality directly influences the electrical performance, reliability, and lifespan of the final product. In PCBs, the foil’s uniformity and adhesion affect trace precision and electrical reliability. In lithium-ion batteries, copper foil acts as the anode current collector; defects such as uneven thickness or surface irregularities can reduce energy efficiency, cycle life, and safety.

A robust test line enables manufacturers to:

-

Evaluate copper foil characteristics under controlled conditions

-

Fine-tune electrolysis process parameters

-

Identify and correct defects such as thickness variation, surface roughness, or mechanical weaknesses

-

Develop new product grades and process recipes

-

Ensure compliance with international quality standards before scaling up production.

Step-by-Step Guide to the Electrolytic Copper Foil Test Line Process

Below is a structured overview of the key stages in the electrolytic copper foil test line process, from raw material preparation to final quality control.

1. Raw Material Preparation and Inspection

Before any electrolysis begins, high-purity raw materials must be verified:

Copper Materials:

High-purity copper cathodes or anodes are inspected for composition and contamination. Techniques such as inductively coupled plasma optical emission spectroscopy (ICP-OES) are commonly used to confirm copper purity levels meet industry standards, typically above 99.99 %.

Electrolyte Solution:

The electrolyte contains copper sulfate and sulfuric acid, along with carefully selected additives designed to influence deposition behavior, surface texture, and mechanical properties. The composition, temperature, and pH of the electrolyte are measured and adjusted to ensure stable electrolysis conditions.

This preparatory stage ensures the foundation for efficient and defect-free copper foil deposition.

2. Electrolytic Deposition

The core of the process takes place inside the electrolytic cell:

Key Components:

-

Cathode Drum: A rotating drum (often titanium with special surface treatments) acts as the deposition surface for copper foil.

-

Anodes: Typically pure copper bars or plates immersed in the electrolyte.

-

Power Supply: Provides controlled current to drive electrolysis.

How It Works:

When electrical current is applied, copper ions migrate through the electrolyte and deposit onto the surface of the cathode drum forming a continuous copper foil layer. Parameters such as current density, bath temperature, electrolyte flow, and additive dosing are tightly controlled to produce uniform thickness and the desired surface texture.

High-resolution sensors and monitoring units measure thickness in real time using techniques such as laser or X-ray gauges, ensuring each meter of foil meets specifications.

3. Filtration and Temperature Control

During electrolysis, filtration and temperature regulation play crucial roles:

-

Filtration Systems: Activated carbon, diatomite, and security filters remove contaminants and maintain electrolyte purity.

-

Temperature Control: Heat exchangers and temperature sensors regulate the electrolyte temperature, as even slight fluctuations can impact deposition quality.

These systems ensure a clean environment and consistent deposition conditions throughout the test run, preventing variations that could compromise foil quality.

4. Peeling, Washing, and Winding

Once a copper layer reaches the target thickness on the drum, it is carefully peeled from the cathode surface:

-

Automated peeling systems ensure the delicate foil separates without damage.

-

The newly formed copper foil is washed to remove residual electrolyte and additives.

-

After drying, the foil is wound onto rolls with controlled tension to ensure no deformation.

This step prepares the material for downstream testing and, eventually, for industrial application.

5. Post-Production Testing and Quality Assessment

This is where engineers verify that the copper foil adheres to all performance criteria:

Thickness Verification:

Using X-ray fluorescence (XRF) and precision micrometers ensures the foil’s thickness is within tolerance.

Surface Roughness:

The roughness impacts adhesion to substrates in PCBs or battery electrodes; tools like atomic force microscopy (AFM) and stylus profilometry assess surface features.

Mechanical Testing:

Tensile strength and elongation are measured using universal testing machines to confirm durability.

Electrical Conductivity:

Four-point probe and eddy current methods determine consistency in electrical performance.

Adhesion Tests:

Peel strength tests assess how well the foil adheres to substrates, which is critical for PCB lamination quality.

Corrosion Resistance:

Salt spray and chemical exposure tests simulate environmental conditions to evaluate long-term performance.

Each of these tests ensures the copper foil meets or exceeds the specifications demanded by highly sensitive technologies such as microelectronics and energy storage.

6. Final Review and Data Integration

After all tests are completed:

-

Engineers consolidate data into a comprehensive report.

-

Statistical analysis tools may be used to identify trends or potential improvements.

-

Successful batches are certified for application; those that don’t meet standards may trigger adjustments in process parameters.

This final step ensures traceability and process control for future production cycles.

Common Questions About Electrolytic Copper Foil Test Line Technology

Q1: What differentiates an electrolytic

www.timonic.com.cn

Timonic