Will tungsten carbide circular saw blades rust?

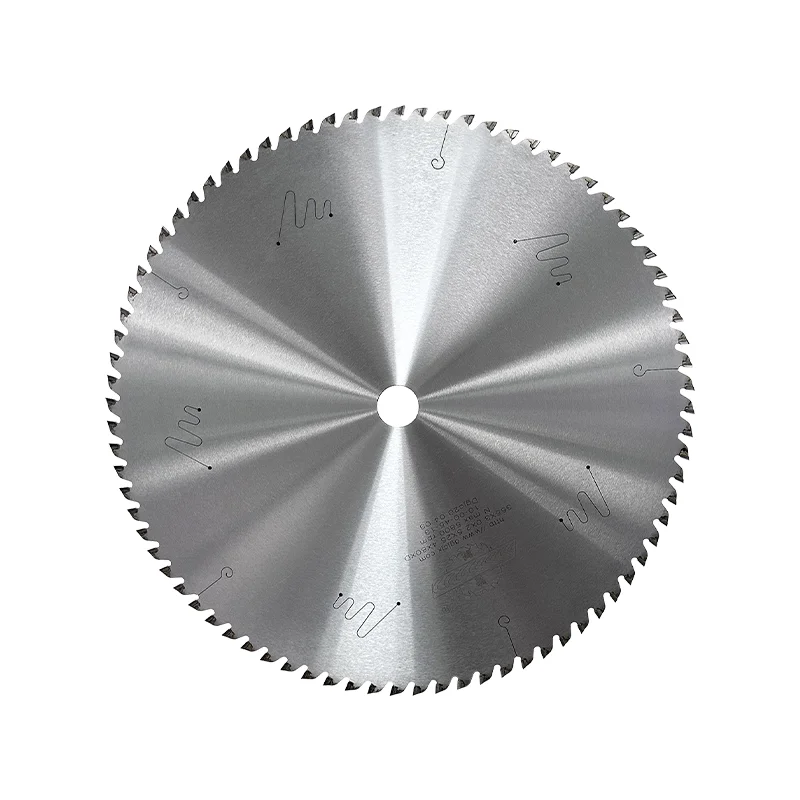

5 min readAmong many industrial cutting tools, tungsten carbide circular saw blades are widely used in many industries such as metal processing, wood cutting, and plastic splitting due to their excellent wear resistance, high hardness, and stable cutting performance. However, many users often raise a key question during long-term use: "Will tungsten carbide circular saw blades rust?" This question seems simple, but it actually involves many aspects such as the metal properties, use environment, and storage methods of tungsten steel materials.

This article will conduct a comprehensive analysis around this issue, and deeply explore whether tungsten carbide circular saw blades are prone to rust, what are the causes of rust, how to prevent rust, and how to deal with rust after it occurs, to help users use and maintain such high-performance tools more scientifically.

1. The material properties of tungsten carbide circular saw blades determine their rust resistance

Tungsten steel is a hard alloy, the main components of which are tungsten carbide (WC) and bonding metal (usually cobalt Co). Tungsten steel is not equivalent to ordinary steel. It has the following core characteristics:

Extremely high hardness: Mohs hardness can reach 9, second only to diamond.

Excellent wear resistance: suitable for long-term high-speed cutting.

Strong corrosion resistance: Its surface is less prone to oxidation than ordinary carbon steel or high-speed steel.

Although tungsten carbide circular saw blades have strong corrosion resistance, they are not "absolutely rust-free". The reason is that the saw blade is usually composed of multiple parts, including the blade head (tungsten steel) and the saw blade body (mostly alloy steel), rather than the entire blade being made of tungsten steel. Therefore, to determine whether it will rust, it is necessary to specifically analyze the material and protection treatment of each part of the saw blade.

2. Analysis of the reasons why tungsten carbide circular saw blades may rust

The saw blade body is not made of all tungsten steel

Most tungsten carbide circular saw blades on the market use an "alloy head + steel matrix" structure, that is, the blade part is welded or brazed to a circular steel matrix with tungsten steel. This design takes into account both cost and performance, but the steel matrix part is more susceptible to oxidation and corrosion than tungsten steel.

Easy to oxidize in high humidity environments

If the saw blade is placed in a high humidity and heavy moisture environment for a long time, especially without anti-rust oil, the steel matrix part is very prone to electrochemical corrosion, resulting in yellow rust or red rust.

Improper use of coolant or cutting fluid

The metal cutting process is often accompanied by the use of coolant. If the liquid pH is not appropriate or the surface of the saw blade is not cleaned in time after use, the residual coolant will accelerate the surface rust.

Improper storage method

The bare chip directly contacts the ground, cement wall, or is stacked with other metal hard objects. When it is damp or under pressure, it will be scratched, oxidized, or even cracked at the edge, forming rust spots.

3. How to prevent tungsten carbide circular saw blades from rusting?

Keep it in a dry environment for storage

The saw blade should be wiped clean of moisture after use and placed in a dry and ventilated environment to avoid moisture. It is recommended to store it in a sealed moisture-proof box when it is not used for a long time, especially in the rainy season in the south.

Apply anti-rust oil regularly

Professional anti-rust oil or industrial lubricant can be applied to the surface of the saw blade to form an oil film to isolate air and moisture and reduce oxidation reactions.

Clean in time after use

The cutting fluid, coolant, and metal powder remaining on the surface of the tungsten steel saw blade should be thoroughly cleaned after each use, and wiped dry with a dry cloth to prevent corrosive substances from adhering for a long time.

Stack and pad in categories

When stacking multiple saw blades, soft spacers should be placed to avoid direct contact between the saw teeth and the saw body, reduce scratches and crushing, and thus reduce the cause of rust.

4. What should I do if the tungsten carbide circular saw blade is rusted?

If the saw blade is found to be partially rusted, the treatment method is as follows:

Mild surface rust

It can be gently wiped with fine steel wool or fine sandpaper, and then coated with anti-rust oil to prevent further oxidation.

Severe rust affects use

If the saw teeth or important stress points have been corroded and pitted, it is recommended to stop using it to prevent breakage or skipping accidents during high-speed rotation.

Send for professional grinding and repair

Some factories provide tungsten carbide circular saw blade grinding services. The technicians will re-grind and debug the blade head, which is suitable for situations where the rust area is not large.

"Will tungsten carbide circular saw blades rust?" The answer is yes, but it depends on the structure of the saw blade, the environment and the maintenance method. Although tungsten steel itself has excellent corrosion resistance, it is often used in combination with steel and welded parts, and there is still a risk of rust.

Therefore, in the process of daily use and maintenance, we should:

Correctly understand the difference between tungsten steel and ordinary steel;

Pay attention to cleaning and rust prevention after use;

Choose a reputable saw blade manufacturer with transparent materials;

Avoid storing unprotected saw blades for a long time in extremely hot and humid environments.

Only in this way can the service life of tungsten carbide circular saw blades be maximized, cutting efficiency can be improved, and safety hazards and maintenance costs can be reduced.

If you are looking for high-performance, corrosion-resistant, and OEM-customizable tungsten carbide circular saw blades, it is recommended to choose a professional manufacturer with industry experience and a strict quality control system to ensure product quality and service life from the source. If you need more tungsten steel saw blade selection suggestions, rust prevention guides, or wholesale quotes, please feel free to contact our technical team.

www.chinechernmachine.com

chinechernmachine