High-Efficiency Single Wall Corrugated Pipe Extrusion Line for Manufacturing

5 min readSingle wall corrugated pipes play a vital role in electrical wiring, automotive circuits, agriculture, and civil engineering. As global demand continues to grow, manufacturers require extrusion systems that deliver precision, consistency, and high output. In this blog post, Jwell Machinery will share the features of single wall corrugated pipe extrusion line for manufacturing, its features, production capabilities, applications, etc.

Understanding the Single Wall Corrugated Pipe Extrusion Line

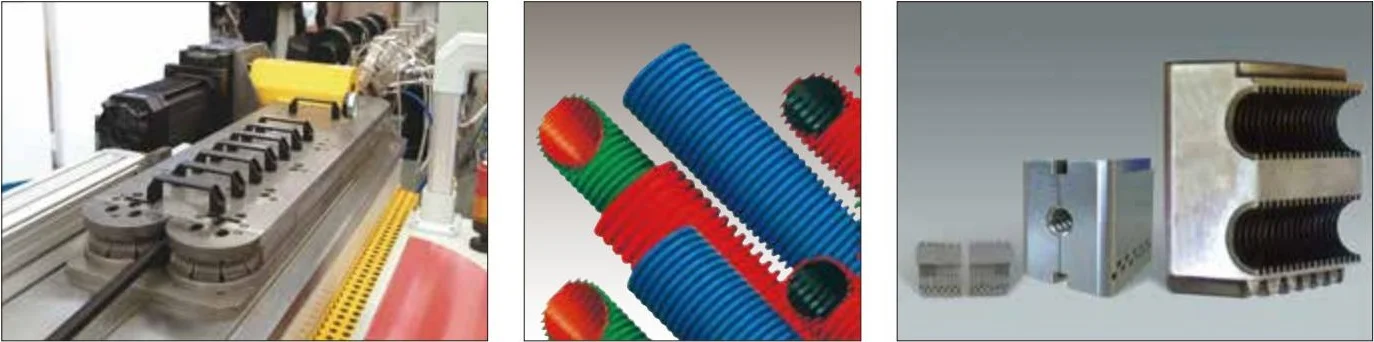

A single wall corrugated pipe extrusion line is engineered to manufacture small-diameter PP, PE, or PA pipes with a uniform corrugated structure. The extrusion process integrates material plasticizing, continuous molding, cooling, and cutting in a streamlined sequence. With a specialized mold, the pipe is shaped in a single forming step, ensuring clarity of the corrugation, high dimensional stability, and smooth pipe surfaces.

These pipes are widely used in wire and cable threading, automotive interior circuit protection, farmland irrigation systems, concrete construction pipelines, and various protective tubing applications. Their lightweight structure, flexibility, impact resistance, and insulation characteristics make them indispensable across multiple industries.

Key Features of Single Wall Corrugated Pipe Production Technology

The corrugated pipe extrusion technology features several engineering advantages that support large-scale, stable production:

-

One-step precision molding

The integrated forming mold enables each pipe to be molded completely in one cycle. This minimizes deformation, improves uniformity, and enhances production efficiency. -

High-quality pipe appearance

The resulting corrugated pipe has smooth, refined surfaces with clear and consistent ripple patterns, ensuring both functional reliability and aesthetic consistency. -

Optimized processing for multiple materials

The line supports PP, PE, PA, and other modified plastic formulations, making it suitable for a wide range of end-use requirements and technical standards. -

Continuous, synchronized operation

Stable extrusion, precise vacuum calibration, and automatic cutting ensure seamless coordination throughout the production process.

Production Capabilities of Single Wall Corrugated Pipe Extrusion Line

The small diameter single wall corrugated pipe extrusion line is specifically designed for compact tubing with strict dimensional requirements. Its production capabilities include:

-

Variable diameter options for threading pipes and circuit protection tubes

-

High-speed forming with continuous corrugator operation

-

Optimized cooling channels to stabilize pipe shape during high-output extrusion

-

Rapid mold exchange design to reduce downtime during size adjustments

The smaller the diameter, the more critical the mold accuracy and cooling uniformity become—areas where advanced extrusion systems demonstrate significant advantages.

Corrugated Pipe Extrusion Equipment from Suzhou Jwell Machinery

Suzhou Jwell Machinery Co., Ltd. serves as a major R&D and manufacturing hub of Jinwei Machinery, providing world-class extrusion systems. Positioned in Chengxiang Industrial Park, Taicang, and only 30 minutes from Shanghai Hongqiao Airport, the company benefits from strategic access to global logistics networks.

Manufacturing Strength

-

Covers 20 hectares with 120,000 m² indoor workshop space

-

Equipped with an advanced CNC machining base for precision component manufacturing

-

Operates standardized assembly workshops for efficient production

-

Employs over 1,000 professional personnel, including expert design engineers and skilled commissioning teams

International Market Presence

More than 75% of the company’s output is exported, supporting global customers with:

-

Strict mechanical design processes

-

Standardized, high-precision manufacturing

-

Comprehensive after-sales and service systems

This ensures high-efficiency, energy-saving, and durable extrusion equipment for long-term industrial use.

Applications of Single Wall Corrugated Pipes in Industry

The versatility of corrugated pipes means they are used in numerous environments requiring flexibility, insulation, and protective structure. Typical applications include:

Wire and Cable Threading Pipe

The lightweight, flexible nature of single-wall corrugated pipe makes it ideal for household wiring conduits, industrial cable channels, and building infrastructure.

Automotive Circuit Protection Tubing

In modern vehicles, corrugated pipes protect electrical harnesses from heat, vibration, and abrasion, ensuring long-term stability of the interior circuit system.

Farmland Irrigation and Drainage

Small-diameter corrugated pipes serve as conduits in agricultural water supply, drainage, and soil improvement systems due to their corrosion resistance and structural flexibility.

Concrete and Building Engineering

These pipes are used inside concrete structures for drainage, cable passage, and ventilation, benefiting from their pressure resistance and long service life.

Advantages of Dedicated Single Wall Corrugated Pipe Extruder

A dedicated corrugated pipe extruder ensures optimized output and long-term reliability. Benefits include:

-

Consistent thermal stability across the extrusion process

-

Reduced material waste due to precise temperature and speed control

-

Lower energy consumption thanks to efficient heating and drive systems

-

Extended equipment lifespan with improved wear-resistant components

These improvements directly translate to lower operational cost and increased production capacity.

System Configuration of the Corrugated Pipe Extrusion Line

A modern extrusion line typically includes:

-

High-efficiency single-screw extruder for plasticizing materials

-

Corrugator and forming molds for shaping the pipe

-

Water-cooling module for stabilizing and finalizing the corrugated structure

-

Automatic cutting system with length measurement

-

Coiler or stacker for final product handling

Each component works in precise coordination to ensure continuous, stable production with minimal manual adjustment.

Why Manufacturers Choose Jwell Corrugated Pipe Extrusion Solutions

Manufacturers rely on Jwell due to the company’s strong engineering foundation and commitment to global service. Key reasons include:

-

Deep expertise in plastic pipe and sheet extrusion equipment

-

Customizable configurations tailored to different pipe standards

-

Reliable worldwide technical support and commissioning assistance

-

Complete lifecycle service from installation to operator training

By focusing on global user needs, Jwell consistently delivers competitive equipment for demanding industrial environments.

Future Development of Single Wall Corrugated Pipe Technology

As markets evolve, the extrusion industry is transitioning toward:

-

Higher automation and digital monitoring

-

Improved energy efficiency and lower carbon emissions

-

More durable mold materials to reduce maintenance

-

Broader compatibility with recycled and eco-friendly polymers

These trends will continue to push corrugated pipe production toward smarter and more sustainable solutions.

Conclusion

The single wall corrugated pipe extrusion line is an essential system for producing protective and functional tubing used across electrical, automotive, agricultural, and construction industries. With advanced molding technology, stable processing, and high production efficiency, it meets the growing global demand for lightweight, durable, and cost-effective pipeline solutions.

Suzhou Jwell Machinery, with its robust manufacturing capability and international service network, remains a leading supplier of high-quality corrugated pipe production equipment. For manufacturers seeking stable performance, technical precision, and long-term reliability, Jwell’s extrusion solutions offer a strong competitive advantage.

If you need, I can also create a shorter version, a Chinese translation, or an SEO keyword list for this article.

www.jwellplas.com

Jwell Machinery