How Swift Clips Tools Improve Job-Site Efficiency and Reduce Labor Costs

3 min readIn the fast-paced world of construction, manufacturing, and industrial assembly, efficiency and cost-effectiveness are critical for maintaining productivity and profitability. One tool that has transformed job-site operations is the Swift Clips tool, designed to streamline fastening and bundling tasks. With advanced automation and precision, these tools help teams save time, reduce labor costs, and improve overall worksite efficiency. Companies like Swift Automation Technology, a global leader in automatic cable tie tools and nylon tie systems, have been at the forefront of innovating solutions that meet these demanding industrial needs.

Understanding Swift Clips Tools

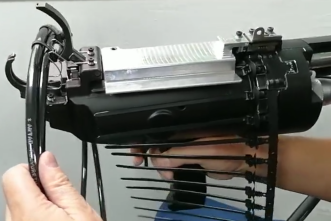

Swift Clips tools, including automatic cable tie machines, hand-held guns, and other fastening devices, are designed to secure cables, wires, pipes, and components quickly and reliably. Unlike traditional manual tying methods, these tools automate repetitive tasks, providing consistent tension, precise placement, and secure fastening every time. By reducing manual effort, Swift Clips tools free up workers to focus on higher-value tasks, enhancing overall productivity.

Key Benefits of Swift Clips Tools

1. Enhanced Job-Site Efficiency

Swift Clips tools significantly speed up fastening processes. Automatic cable tie machines can bundle multiple wires or components in a fraction of the time it would take manually. This rapid operation not only accelerates project timelines but also ensures uniform and professional results across every task. Swift Automation Technology’s range of automatic tools guarantees consistent performance, even in high-volume applications.

2. Reduced Labor Costs

Manual bundling is labor-intensive, especially in large-scale projects with extensive wiring, piping, or assembly requirements. By automating this process, Swift Clips tools minimize the need for additional labor, reducing overall operational costs. Companies can allocate personnel to more complex and value-added tasks, maximizing workforce efficiency and lowering project expenses.

3. Consistent and Reliable Performance

One of the key advantages of Swift Clips tools is the precision and reliability they bring to fastening tasks. Each tie is applied with consistent tension, reducing the risk of loose connections or uneven bundling. For industries such as electrical assembly, manufacturing, or construction, this consistency enhances product quality, reduces errors, and minimizes rework.

4. Versatility Across Applications

Swift Clips tools are designed to handle a wide range of applications—from securing cables and wires to fastening hoses, pipes, or packaging materials. Swift Automation Technology offers a variety of tools and compatible nylon ties to suit different industrial scenarios, ensuring that no job is too large or complex for efficient automation.

5. Safety and Ergonomics

Manual tying can strain workers’ hands, wrists, and arms over time, leading to fatigue and potential injuries. Swift Clips tools are ergonomically designed to reduce repetitive strain, allowing operators to work comfortably for extended periods. This focus on safety and ergonomics not only improves productivity but also promotes a healthier work environment.

Swift Automation Technology: Driving Innovation in Fastening Solutions

Swift Automation Technology is a global leader in the development and manufacturing of automatic cable tie machines, hand tools, and compatible nylon tie systems. Their expertise spans high-quality automatic tools for diverse industrial applications, offering solutions that improve operational efficiency, reduce labor costs, and enhance workplace safety. Swift Automation Technology continually innovates to provide scalable, reliable, and cost-effective fastening solutions that meet the evolving needs of industrial professionals worldwide.

Conclusion

Swift Clips tools are more than simple fastening devices—they are a powerful solution for improving job-site efficiency, reducing labor costs, and ensuring consistent, high-quality results. By integrating automatic cable tie machines and hand tools from Swift Automation Technology, companies can streamline operations, optimize workforce utilization, and achieve faster project completion.

For construction, manufacturing, and industrial assembly teams, adopting Swift Clips tools is a strategic move toward more efficient, cost-effective, and safe operations. With innovation at the forefront, Swift Automation Technology continues to deliver tools that redefine what’s possible in industrial fastening and cable management.

www.sz-swift.com

Shenzhen Swift Automation Technology Co., Ltd.