Precision Herringbone Gear Applications: Engineering Excellence in Motion

5 min readIntroduction to Precision Herringbone Gears

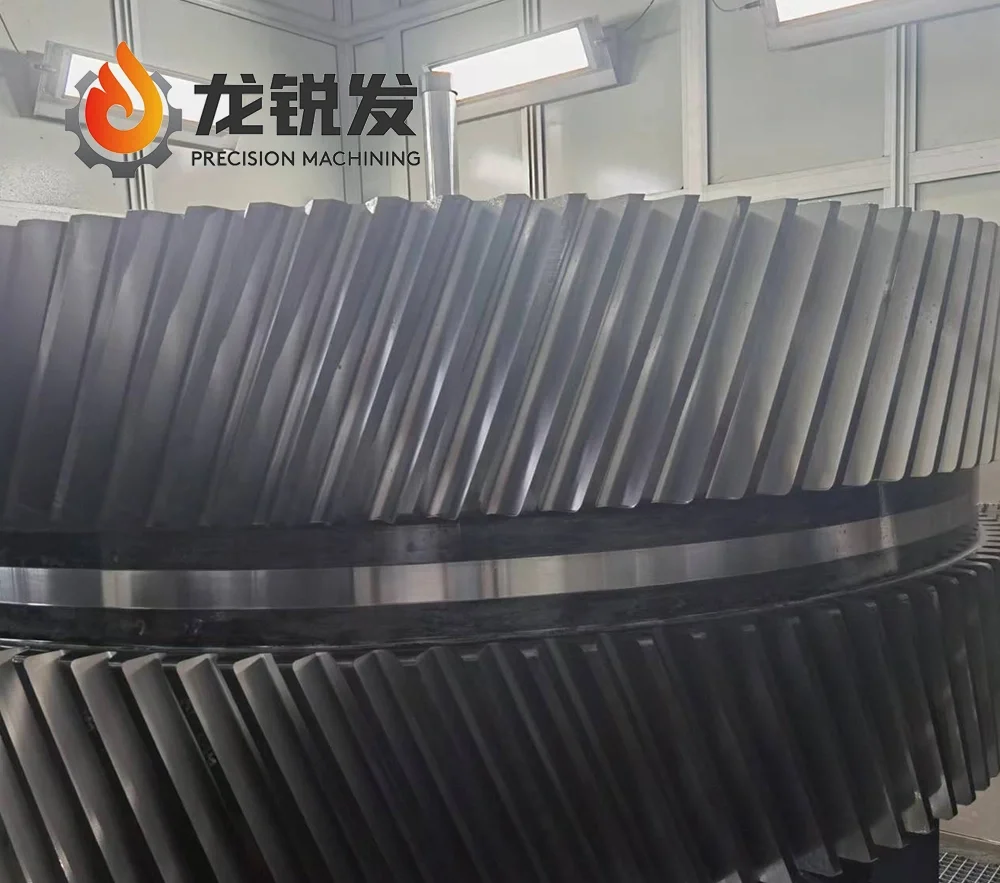

In the realm of mechanical power transmission, precision herringbone gears occupy a distinctive position. Characterized by their double helical tooth pattern, these gears merge the operational benefits of spur and helical gears while eliminating certain drawbacks. The opposing helix angles cancel out axial thrust, while the continuous tooth engagement ensures smoother operation and higher load-carrying capacity.

Manufactured with tight tolerances and specialized materials, precision herringbone gears are used in applications where accuracy, durability, and efficiency are non-negotiable. Their design enables stable torque transmission in heavy-duty and high-speed environments, making them indispensable in sectors from marine propulsion to aerospace engineering. In this blog post, as a professional industrial gear manufacturing factory, Longruifa will share high precision herringbone gear applications.

Key Advantages of Precision Herringbone Gears

Before exploring their applications, it is essential to understand why these gears are preferred in demanding industries:

-

Axial Thrust Elimination – The mirrored helix structure inherently balances forces, removing the need for thrust bearings in many cases.

-

High Load Capacity – The large surface contact area distributes loads efficiently, supporting heavy-duty applications.

-

Smooth Operation – Continuous tooth engagement minimizes vibration, noise, and wear.

-

Enhanced Durability – Precision machining and material selection increase resistance to fatigue and deformation.

These benefits make precision herringbone gears a preferred solution where performance and longevity are equally critical.

1. Marine Propulsion Systems

Smooth Power Transmission in Large Vessels

In marine engineering, propulsion systems demand robust components capable of enduring prolonged high loads under harsh environmental conditions. Precision herringbone gears are extensively used in ship propulsion gearboxes, where they transmit engine power to propeller shafts efficiently and reliably.

The absence of axial thrust is particularly beneficial in marine gearboxes, reducing stress on bearings and ensuring long-term operational stability. Additionally, the smooth torque transfer helps minimize vibration, enhancing comfort for crew and passengers while protecting other mechanical components from undue stress.

2. Power Generation and Turbomachinery

Supporting Continuous, High-Speed Operation

In gas turbines, steam turbines, and hydroelectric plants, gear systems must sustain continuous operation at high rotational speeds. Precision herringbone gears excel in this role due to their ability to maintain accurate alignment under thermal expansion and heavy loads.

For example, in turbogenerators, these gears connect high-speed turbine shafts to slower-speed generators, ensuring consistent and efficient energy transfer. Their low vibration characteristics also reduce wear on adjacent components, directly contributing to lower maintenance costs and extended service life in critical infrastructure.

3. Oil and Gas Industry Equipment

Reliability in Harsh Operating Environments

The oil and gas sector demands equipment that can withstand extreme temperatures, corrosive environments, and heavy mechanical loads. Precision herringbone gears are deployed in drilling rigs, compressor drives, and offshore platform machinery, where downtime is costly and potentially hazardous.

Their robust tooth geometry allows for the transfer of substantial torque without slippage, while the absence of axial forces reduces bearing wear in remote or hard-to-service installations. In offshore platforms, where space is limited, compact herringbone gear arrangements can provide high power density without sacrificing stability.

4. Aerospace and Defense Applications

Precision Under Extreme Conditions

The aerospace sector relies on uncompromising accuracy and performance. Precision herringbone gears are utilized in jet engine accessory drives, helicopter transmissions, and defense equipment where alignment precision and vibration control are vital.

For helicopters, these gears facilitate stable transmission of power from the engine to the rotor system, reducing oscillations that could affect flight stability. In military vehicles and naval vessels, herringbone gears provide reliable power delivery in mission-critical situations, where even minor malfunctions can have significant consequences.

5. Industrial Machinery and Heavy Equipment

Maximizing Productivity and Efficiency

From steel mills to paper processing plants, industrial machinery often requires continuous, high-load operation. Precision herringbone gears are used in rolling mills, conveyor drives, and large-scale compressors, where torque demands and reliability requirements are substantial.

In these applications, gear failure can halt production entirely, leading to financial losses. The enhanced load distribution and wear resistance of herringbone gears minimize the risk of sudden breakdowns, thereby increasing uptime and overall productivity.

6. Mining and Material Handling Systems

Handling Extreme Loads with Stability

Mining operations involve machinery that moves immense volumes of material under challenging environmental conditions. Precision herringbone gears are common in crushers, conveyors, and hoists, where they endure repetitive heavy shock loads.

The stability provided by their tooth engagement pattern reduces misalignment under load, ensuring smooth operation even when subjected to fluctuating torque. This capability helps maintain safe and efficient operations in remote locations where repairs are logistically challenging.

7. Wind Energy Systems

Sustainable Power with Mechanical Reliability

In wind turbines, gearbox reliability is crucial for maximizing power output and minimizing downtime. While planetary gear systems are common, precision herringbone gears are integrated into certain main gear stages for their ability to handle variable wind loads without generating harmful axial forces.

The smooth meshing action contributes to quieter turbine operation, which is increasingly valued in offshore wind farms where environmental noise considerations are part of regulatory compliance.

Precision Manufacturing for Precision Performance

The performance of herringbone gears is directly tied to their manufacturing quality. Modern production involves CNC gear hobbing, grinding, and precision inspection using coordinate measuring machines (CMM). Material selection, often including alloy steels with surface hardening treatments, ensures the gears can withstand their intended operational environments.

Tolerances are maintained within microns to ensure perfect tooth alignment, which is critical for the vibration-free operation demanded in aerospace, marine, and power generation applications.

Maintenance Considerations

While precision herringbone gears are engineered for durability, proper maintenance is essential to their long-term reliability. This includes:

-

Lubrication Management – Using the correct viscosity and maintaining oil cleanliness to prevent pitting or scoring.

-

Alignment Checks – Ensuring shafts remain in tolerance to prevent uneven loading.

-

Condition Monitoring – Employing vibration analysis and thermal imaging to detect early signs of wear.

Proactive maintenance not only extends gear life but also safeguards associated machinery from damage due to gear failure.

Conclusion

Precision herringbone gears are more than just mechanical components—they are enablers of efficiency, stability, and performance across a wide range of industries. Their unique tooth geometry, combined with high-precision manufacturing, allows them to excel in marine propulsion, power generation, aerospace, oil and gas, heavy industry, mining, and renewable energy systems.

By eliminating axial thrust, reducing vibration, and handling substantial loads with precision, these gears stand as a testament to engineering innovation. As industries continue to push for greater efficiency and reliability, the applications of precision herringbone gears will remain both vital and expansive.

www.lrfgears.com

Longruifa