Understanding the Titanium Cathode Drum PVA Polishing Machine: Principles and Applications

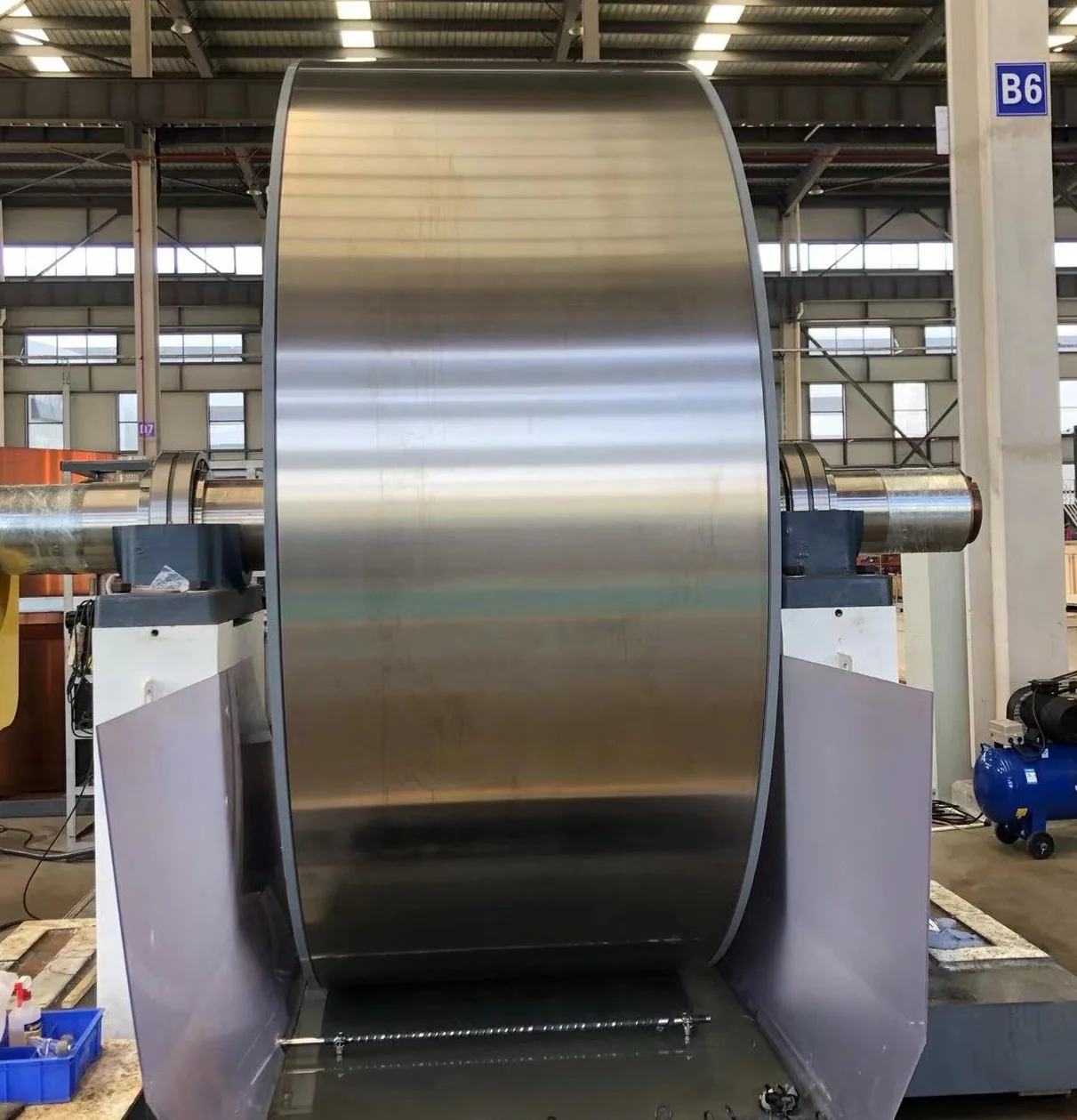

4 min readIn the modern era of advanced materials and energy technology, precision surface treatment plays a decisive role in determining product performance and reliability. Among the many critical processes in the production of high-quality copper foil—especially for lithium-ion batteries—the Titanium Cathode Drum PVA Polishing Machine stands out as a key piece of equipment. Designed for turning and polishing titanium drums, this machine ensures that copper foils achieve the uniformity, smoothness, and durability required across a variety of high-tech industries.

Exploring the Function of the Titanium Cathode Drum Polishing Machine

The Titanium Cathode Drum PVA Polishing Machine is primarily used for surface finishing of titanium drums employed in the electrolytic production of copper foil. During the electrolysis process, the titanium drum serves as the cathode on which copper layers are deposited. To ensure that the resulting copper foil meets strict quality standards, the drum’s surface must be precisely polished and defect-free.

The PVA (Polyvinyl Alcohol) polishing process utilizes specialized abrasive wheels and controlled polishing parameters to achieve a mirror-like surface finish. This process removes surface irregularities, oxides, and micro-imperfections, enabling superior adhesion and uniform copper deposition.

A finely polished titanium drum directly influences the thickness consistency, surface gloss, and mechanical strength of the copper foil produced. It also minimizes the risk of pinholes, uneven texture, and impurities—ensuring that the final foil performs flawlessly in demanding applications.

Importance in Copper Foil Manufacturing

Copper foil is a core material in various modern industries, especially in lithium-ion batteries, copper-clad laminates (CCL), and printed circuit boards (PCB). The performance and stability of these products depend heavily on the quality of the copper foil substrate.

For lithium-ion batteries, copper foil acts as the current collector for the anode. Any surface inconsistency or defect in the foil can affect the electrochemical stability, energy density, and lifespan of the battery. Similarly, in PCB manufacturing and 5G communication devices, copper foil must provide excellent conductivity, smoothness, and high bonding strength.

The titanium cathode drum polishing machine ensures that copper foils meet the stringent standards required for:

Standard copper foils used in everyday electronics.

High-temperature and high-elongation foils used in flexible or thermal-resistant applications.

Low-profile foils required in high-frequency or fine-line circuit designs.

Through precision polishing, the equipment directly contributes to the performance, consistency, and competitiveness of copper foil materials across multiple sectors.

Principles Behind PVA Polishing Technology

The PVA-based polishing technique is built around the use of a soft yet highly elastic abrasive medium, which enables fine polishing without damaging the titanium drum’s surface. Compared with conventional abrasive methods, PVA polishing achieves better control over roughness and significantly extends the drum’s operational life.

The process typically involves a combination of rotational movement, controlled pressure, and cooling systems to maintain stable temperature and avoid deformation. The result is a uniform surface texture with optimal smoothness, which is critical for achieving high-quality electroplated copper foils.

Furthermore, the use of environmentally friendly PVA materials supports sustainable production practices, aligning with the global shift toward greener industrial processes.

Timonic’s Expertise and Technological Innovation

Timonic is a high-tech enterprise committed to the research, development, and manufacturing of production equipment for new energy lithium battery materials. With a focus on innovation and precision engineering, Timonic has developed a comprehensive range of equipment, including lithium battery copper foil production lines, cathode rollers, and other specialized components that enhance manufacturing efficiency and product performance.

The company’s Titanium Cathode Drum PVA Polishing Machine reflects its deep understanding of metallurgical precision, surface science, and production automation. Each machine is built to deliver consistent quality, reduce operational downtime, and meet the evolving needs of industries that demand high-performance materials.

By integrating advanced control systems, intelligent monitoring, and precision machining, Timonic ensures that every piece of equipment not only meets international standards but also contributes to the sustainable and efficient development of the new energy industry.

The Expanding Role of Precision Equipment in the Energy Industry

As global demand for lithium-ion batteries and high-performance electronic materials continues to surge, precision manufacturing equipment like the Titanium Cathode Drum PVA Polishing Machine becomes ever more vital. The transition to cleaner energy solutions, electric vehicles, and smart devices depends on materials that are engineered at the microscopic level for consistency and reliability.

Companies investing in advanced production technologies are gaining a competitive edge by improving yield rates, reducing waste, and ensuring long-term performance stability. Timonic’s continuous innovation in polishing and production equipment reinforces the foundation upon which these modern technologies are built.

Conclusion

The Titanium Cathode Drum PVA Polishing Machine plays an indispensable role in producing high-quality copper foils used across industries ranging from lithium-ion batteries to PCB and 5G communications. Its precision polishing capability ensures flawless surfaces, improved material performance, and higher production efficiency.

As a pioneer in the field, Timonic remains dedicated to driving innovation in new energy material equipment, providing cutting-edge solutions that empower global manufacturers to achieve excellence in quality, sustainability, and technological advancement. Through continuous research and commitment to excellence, Timonic is shaping the future of energy and material manufacturing—one polished surface at a time.

High-Performance Solutions for Electrodeposited Copper Foil Manufacturing Equipment

www.timonic.com.cn

Timonic