How to Choose the Right Pulley PowerGrip for Your Machinery

3 min readWhen it comes to high-precision machinery, one of the most critical components affecting performance, durability, and efficiency is the pulley system. Among the various options available on the market, PowerGrip pulleys—known for their precise timing, excellent grip, and smooth power transmission—have become the go-to choice for a wide range of industrial applications.

Whether you're upgrading existing machinery or designing a new system, selecting the right PowerGrip pulley is essential to ensuring optimal mechanical performance. In this article, we’ll guide you through the key considerations for choosing the right pulley and introduce how Hetuoda Machinery Manufacturing can support your custom and OEM needs with high-quality, precision transmission components.

What Is a PowerGrip Pulley?

A PowerGrip pulley is a type of timing pulley designed to work with a synchronous (timing) belt, offering non-slip power transmission and precise motion control. These pulleys are widely used in applications requiring accurate positioning, such as:

-

CNC machinery

-

3D printers

-

Packaging equipment

-

Textile machines

-

Robotics and automation systems

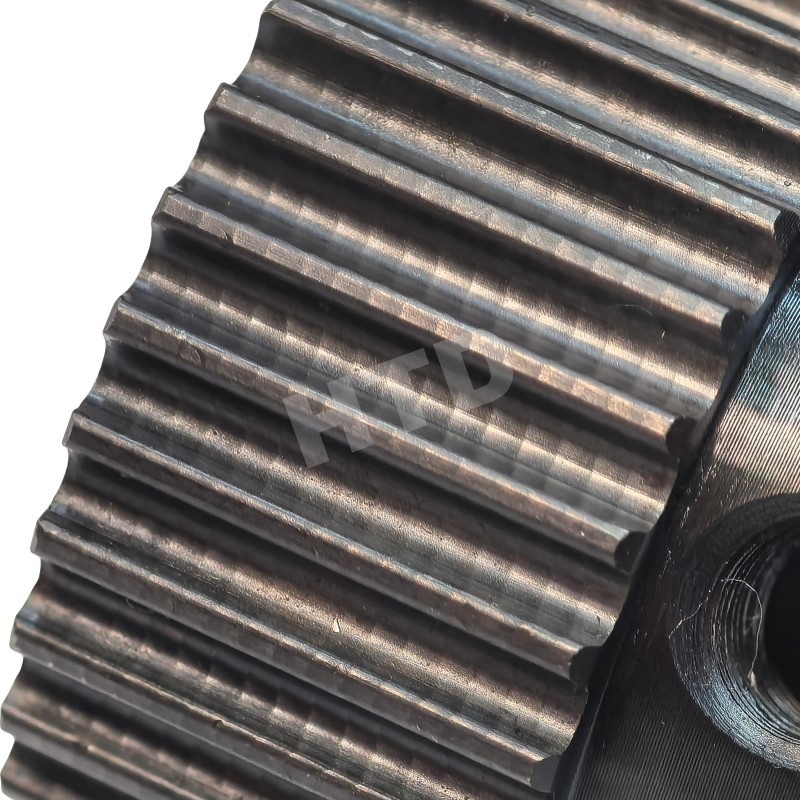

PowerGrip pulleys are designed with grooved teeth that perfectly mesh with the matching belt, ensuring synchronized rotation between shafts without slippage.

Key Factors to Consider When Choosing a PowerGrip Pulley

1. Pulley Profile and Tooth Pitch

Start by identifying the correct tooth profile (e.g., HTD, GT2, GT3, T5, etc.) and pitch size, which refers to the distance between teeth. Matching these with your timing belt is critical for proper engagement and performance.

2. Material Selection

PowerGrip pulleys are typically made from aluminum, steel, or engineering plastics. The choice depends on your operating conditions:

-

Aluminum: Lightweight and corrosion-resistant, ideal for high-speed and low-load applications

-

Steel: High strength and wear resistance for heavy-duty environments

-

Plastic: Cost-effective and quiet operation in light-load systems

Hetuoda offers a full range of materials and can customize pulley specifications based on your machinery’s load, speed, and environmental conditions.

3. Bore Type and Fitment

Choosing the right bore type (plain bore, taper bore, or keyway) ensures a secure fit to the shaft. Hetuoda supports customized inner bores, keyways, and set screw configurations for a seamless fit into your system.

4. Number of Teeth and Pulley Diameter

The number of teeth affects the transmission ratio and torque output. Ensure the pulley’s size meets your torque and speed requirements without compromising belt life or introducing vibration.

5. Balance and Precision

For high-speed applications, it’s vital to select a high-precision machined pulley that offers excellent concentricity and minimal runout. Poorly balanced pulleys can cause belt wear, noise, and equipment damage.

Hetuoda’s pulleys are manufactured using CNC machining with strict quality control, ensuring precise tooth formation and dynamic balance.

Why Hetuoda Machinery Manufacturing?

Hetuoda Machinery Manufacturing Co., Ltd. specializes in producing high-precision transmission parts and provides comprehensive OEM and customization services. Their product range includes:

-

Timing pulleys (PowerGrip, HTD, GT, T-series, etc.)

-

Tensioners and tightening sleeves

-

Gears and gear plates

-

Machined metal parts for various industries

With advanced production equipment, CAD/CAM design systems, and ISO-compliant quality management, Hetuoda delivers durable, performance-driven parts for demanding industrial applications.

Their pulleys are widely used in industries such as:

-

Automation and robotics

-

Packaging and printing

-

Automotive components

-

Medical and lab equipment

-

Aerospace and energy systems

Final Thoughts

Choosing the right PowerGrip pulley is more than just matching specs—it's about ensuring mechanical synergy, precision, and reliability throughout your entire drive system. By carefully considering pulley profile, material, bore type, and application needs, you can significantly improve system efficiency and reduce maintenance downtime.

With Hetuoda Machinery Manufacturing as your trusted supplier, you gain access to custom-engineered pulleys, expert support, and OEM manufacturing services that meet the highest standards of quality and precision. Whether you're building new machines or retrofitting existing ones, Hetuoda ensures your power transmission is smooth, accurate, and built to last.

www.cdepulley.com

Suzhou Hetuoda Machinery Manufacturing Co., Ltd.