How to Choose the Right UV Recombine Machine for Your Needs

3 min readIn the realm of micro and nanofabrication, UV recombine machines play a pivotal role in replicating intricate structures onto larger substrates. These machines are essential for applications ranging from holography to advanced optics. Selecting the appropriate UV recombine machine is crucial to ensure optimal performance, efficiency, and product quality. This guide aims to provide a comprehensive overview to assist you in making an informed decision.

Understanding UV Recombine Machines

A UV recombine machine utilizes ultraviolet light to transfer micro or nanostructures from a master template onto a substrate. This process, often referred to as UV nanoimprint lithography or UV embossing, is fundamental in producing high-fidelity replicas of structures as small as 10 nanometers. The technology is widely employed in creating holograms, diffractive optical elements, and other micro-structured surfaces.

Key Factors to Consider When Choosing a UV Recombine Machine

1. Precision and Accuracy

The ability to replicate structures with high fidelity is paramount. Machines that offer precise alignment and positioning systems ensure that the replicated patterns maintain the integrity of the original design. For instance, some advanced systems boast step accuracy up to 1 micron, ensuring minimal deviation from the master template.

2. Substrate Size Compatibility

Consider the maximum substrate size the machine can accommodate. Depending on your production requirements, you may need a machine that can handle larger substrates to increase throughput and reduce processing time. Some machines are designed to process substrates up to 300x300mm or customized sizes based on client needs.

3. Throughput and Efficiency

Evaluate the machine's processing speed and its ability to handle high-volume production without compromising on quality. Machines equipped with features like continuous image replication and high-speed operation can significantly enhance production efficiency.

4. Versatility in Applications

Depending on your industry and application, you might require a machine capable of handling various materials and structures. Some UV recombine machines are versatile enough to work with different substrates and can replicate a range of structures, from holographic images to micro-lens arrays.

5. Integration with Existing Systems

Ensure that the machine can be seamlessly integrated into your current production line. Compatibility with existing equipment and software can reduce setup time and costs.

6. Maintenance and Support

Opt for machines from reputable manufacturers that offer robust customer support and maintenance services. Regular maintenance is crucial to keep the machine operating at peak performance and to prolong its lifespan.

Types of UV Recombine Machines

Understanding the different types of UV recombine machines can further aid in making an informed choice:

1. Step-and-Repeat UV Imprinters

These machines use a step-and-repeat process to upscale micro and nanostructures to larger surface areas. They are ideal for applications requiring seamless integration of structures over expansive substrates.

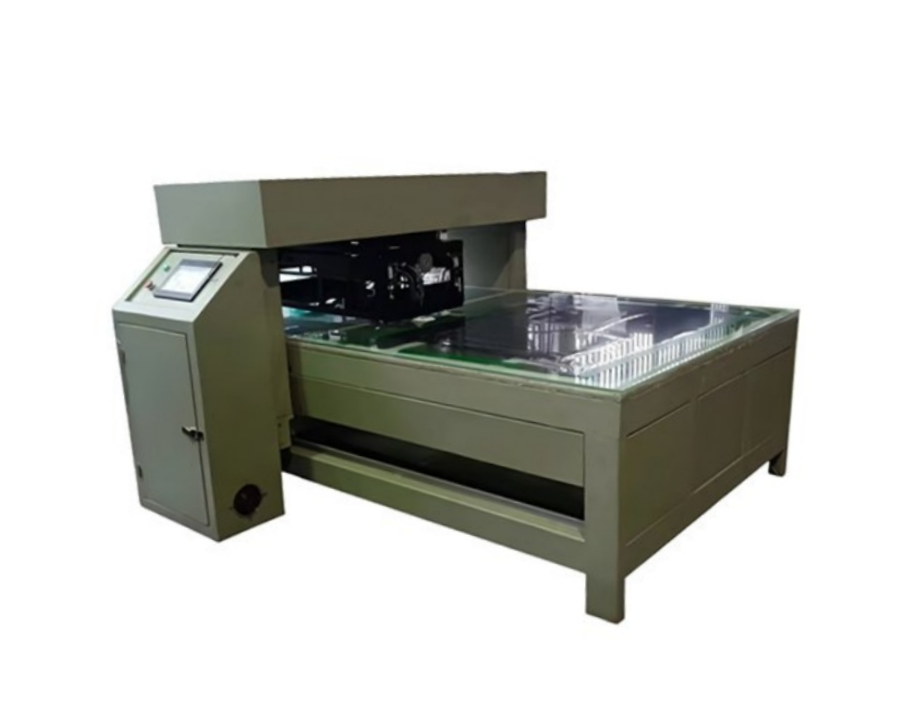

2. Fully Automatic Hologram UV Recombiners

Designed specifically for holographic applications, these machines automate processes like positioning, glue coating, image copying, and exposure. They are suitable for large-scale production of holographic images.

hologramproject.com

3. UV LED Nanoimprint Systems

Utilizing UV LED technology, these machines offer high-precision replication of nanostructures. They are known for their energy efficiency and are suitable for applications requiring high accuracy.

Applications of UV Recombine Machines

UV recombine machines find applications across various industries:

Holography: Production of security features for currency, identification cards, and branded products.

Optics: Manufacturing of diffractive optical elements and micro-lens arrays.

Packaging: Creation of decorative and functional holographic packaging materials.

Electronics: Fabrication of micro and nanoscale components for electronic devices.

Making the Final Decision

When selecting a UV recombine machine:

1. Assess Your Specific Needs: Clearly define the structures you intend to replicate, the materials you'll use, and the production volume.

2. Research Manufacturers: Look for manufacturers with a proven track record in producing reliable and high-quality machines.

3. Request Demonstrations: If possible, arrange for a demonstration to observe the machine's performance firsthand.

4. Consider Total Cost of Ownership: Beyond the initial purchase price, factor in maintenance costs, potential downtime, and energy consumption.

5. Seek Feedback: Consult with industry peers or existing users to gain insights into their experiences with specific machines.

By meticulously evaluating these factors and aligning them with your operational requirements, you can select a UV recombine machine that enhances your production capabilities and delivers high-quality results.

The Role of UV Recombine Machines in the Printing Industry

www.zhhologram.com

Wuxi Zhongheng New Anti Counterfeiting Technology Co., Ltd.