Automotive Rubber Hose: Essential Performance Factors and Maintenance Best Practices

5 min readIn modern automotive engineering, the automotive rubber hose plays a vital role in ensuring the reliability, safety, and efficiency of vehicles. While these hoses may appear to be simple flexible tubes, they are in fact highly engineered components designed to operate under demanding mechanical and environmental conditions. Their ability to transport critical fluids and gases safely depends on two key factors: their performance characteristics and their maintenance and quality assurance standards.This article Hanxiang provides an in-depth analysis of these two dimensions, offering technical insights into what makes an automotive rubber hose dependable in real-world applications.

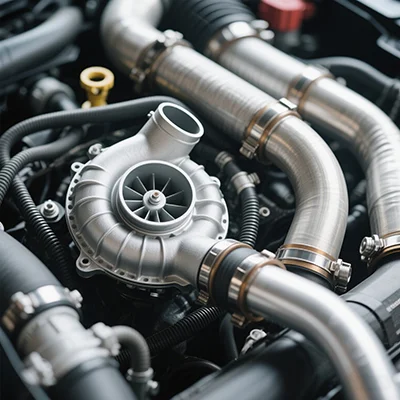

Performance Characteristics of Automotive Rubber Hose

The performance of an automotive rubber hose is determined by how well it withstands the physical, chemical, and environmental challenges present in different automotive systems. Engineers must carefully evaluate these characteristics to ensure the right hose is specified for each application.

1. Temperature Resistance

Automotive environments expose hoses to a wide range of temperatures, from sub-zero cold starts to the extreme heat generated in engine compartments. A reliable automotive rubber hose must function across this entire spectrum without degradation.

-

Cold resistance: High flexibility at temperatures as low as -40°C ensures hoses remain pliable and do not crack during winter operation.

-

Heat resistance: Sustained exposure to 120°C or more near engine blocks requires high-grade elastomers like EPDM.

-

Thermal cycling: Constant expansion and contraction caused by heating and cooling cycles must not compromise structural integrity.

2. Pressure Endurance

The ability to tolerate internal pressure is critical for an automotive rubber hose, particularly in systems where fluids are transmitted under force.

-

Static pressure tolerance ensures hoses maintain shape and function under constant loads.

-

Dynamic pressure endurance allows them to handle rapid pressure spikes, such as those in hydraulic systems.

-

Burst strength testing confirms the hose will not rupture even under pressures significantly above normal operating conditions.

3. Chemical Compatibility

Automotive fluids can be aggressive and cause rapid deterioration of materials if the hose is not designed correctly.

-

Fuel resistance: Hoses must handle gasoline, diesel, and ethanol blends without swelling or cracking.

-

Coolant compatibility: Glycol-based antifreeze requires elastomers resistant to chemical corrosion.

-

Oil and hydraulic fluids: Nitrile and fluoroelastomer-based hoses provide superior resistance to oil breakdown.

A lack of chemical compatibility can result in leaks, contamination, or even system failure.

4. Flexibility and Bend Radius

Vehicle designs often involve tight spaces with complex routing paths. An automotive rubber hose must maintain performance even when bent at sharp angles.

-

Tight bend radius capability prevents kinking or collapsing of the hose.

-

Vibration absorption ensures that engine and chassis vibrations do not transmit stress to connections.

-

Ease of installation is improved by hoses that retain flexibility without sacrificing strength.

5. Durability and Longevity

Durability is an essential measure of hose quality, especially given the harsh environments they face.

-

Ozone and UV resistance protects hoses from external atmospheric conditions.

-

Abrasion resistance prevents external wear from rubbing against engine parts.

-

Fatigue life ensures hoses can withstand millions of cycles of pressure fluctuations without failure.

A durable automotive rubber hose minimizes downtime and reduces replacement costs, directly contributing to overall vehicle reliability.

Maintenance and Quality Assurance of Automotive Rubber Hose

Even the highest-quality hose requires proper maintenance and adherence to rigorous quality standards. This section highlights best practices for extending the life of an automotive rubber hose and ensuring that it consistently meets safety and performance requirements.

1. Routine Inspection and Preventive Maintenance

Regular inspection is the first line of defense against hose-related failures.

-

Visual inspection: Check for cracks, swelling, hardening, or surface blistering.

-

Leak detection: Look for fluid seepage around joints or along the hose body.

-

Tactile checks: Feel for soft spots or irregular stiffness, which indicate internal degradation.

-

Scheduled replacement: Even without visible damage, hoses should be replaced after 4–6 years to avoid age-related failures.

Proactive maintenance prevents minor issues from escalating into major safety hazards.

2. Common Failure Modes

Understanding how an automotive rubber hose typically fails helps technicians identify problems early.

-

Surface cracking caused by ozone exposure.

-

Internal swelling due to chemical incompatibility with fluids.

-

Bursting from exceeding pressure ratings.

-

Abrasion wear from contact with sharp edges or moving parts.

Identifying these signs early enables timely corrective action.

3. Proper Installation Practices

Even the best hoses can fail prematurely if installed incorrectly.

-

Correct routing avoids contact with hot surfaces and sharp edges.

-

Appropriate clamping secures the hose without cutting into it.

-

Allowance for expansion prevents tension under thermal cycling.

-

Clean connectors ensure leak-free connections.

Installation quality is as important as product quality in determining service life.

4. Compliance with Industry Standards

A reputable automotive rubber hose must be manufactured and tested according to recognized industry standards.

-

SAE standards specify pressure ratings, material requirements, and dimensional tolerances.

-

ISO certifications demonstrate global compliance with performance and safety benchmarks.

-

OEM specifications ensure compatibility with manufacturer-specific requirements.

Compliance assures customers that the hose has been validated for real-world performance.

5. Supplier Quality Assurance

Choosing a reliable supplier is crucial for long-term success. An effective supplier will:

-

Maintain stringent quality control at every stage of production.

-

Provide documentation and traceability for each batch.

-

Offer technical support for installation and troubleshooting.

-

Guarantee consistent delivery for large-scale manufacturing needs.

Working with certified and experienced suppliers ensures a stable supply chain and minimizes risks associated with inferior products.

The automotive rubber hose is far more than a simple connector—it is a high-performance component that directly influences the safety, efficiency, and durability of vehicles. By focusing on performance characteristics such as temperature resistance, pressure endurance, chemical compatibility, flexibility, and durability, engineers can ensure hoses deliver reliable operation under demanding conditions. Equally important, rigorous maintenance and quality assurance practices, including regular inspection, preventive replacement, adherence to industry standards, and working with reputable suppliers, ensure long service life and consistent performance. Incorporating these two pillars—performance and quality assurance—into every aspect of hose selection and management guarantees that vehicles continue to operate safely and efficiently, no matter the conditions.

https://www.hanxiangrubber.com/Rubber-Hoses

www.hanxiangrubber.com

Dongguan Hanxiang Rubber Products Co., Ltd.